The extent to which an external magnetic field can influence the operation of Spin-Transfer-Torque Magnetic Random Access Memory (STT-MRAM) remains a critical question within the microelectronics industry in particular regarding its use in automotive industry. SPINTEC is actively engaged in an international technical group comprising academic and industrial experts in MRAM technology, with a particular focus on addressing this issue. Under the leadership of SPINTEC, IBM, Hprobe and NUMEM, an application note on this topic was published in the Fall 2024 issue of IEEE Electron Devices Magazine.

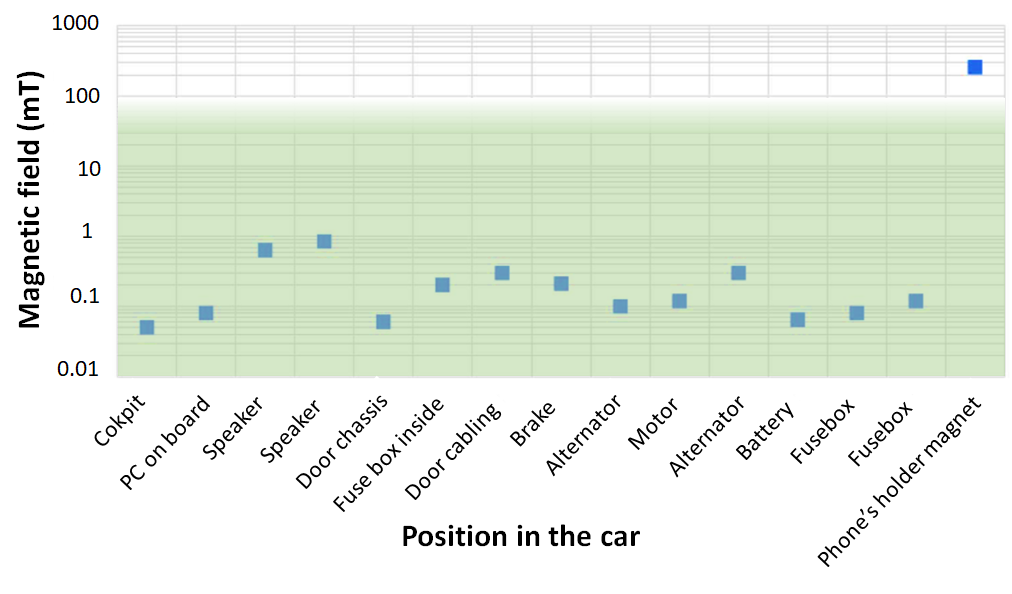

Magnetic field in a car measured at different positions. The green background indicates the safe use zone.[/caption]

STT-MRAM are magnetic devices based on magnetic tunnel junctions. As any magnetic device, they exhibit a certain sensitivity to parasitic magnetic field that can arise from nearby permanent magnets or current flows. Industrial players producing microcontrollers in particular for automotive industry are concerned by such sensitivity which may potentially affect the system security. Commercial STT-MRAM exhibit large coercive field (0.2 T – 0.5 T) which makes them quite robust against magnetic field perturbation in standby mode. However, during write, external magnetic field can change the current required to write the cell. The STT-MRAM manufacturers guaranty that the failure rate during write remains negligible as long as the parasitic magnetic field does not exceed a few tens of mT to one hundred mT depending on MRAM target application (embedded FLASH (eFlash) or stand-alone). These are still quite high fields, which are not encountered in most applications except in very special cases. As a result, we show that the magnetic immunity of STT-MRAM is sufficient for most uses once the chip is mounted on a printed circuit board or inserted in its working environment. This statement is supported by the experience acquired during 60 years of use of magnetic hard disk drives, 20+ years of use of magnetic field sensors as position encoders in the automotive industry, and 15+ years of use of earlier generations of MRAM. Mainly, during chip handling, caution does need to be exercised to avoid exposing the chip to excessively high magnetic fields.

As an illustration, the figure shows the magnetic field at various locations in a car. It is always much below the specified maximum field for STT-MRAM error-free operation. Only in direct contact with a permanent magnet (for instance in contact with a magnetic phone holder), the field may locally exceed the maximum specified value. However, even in this case, the issue may be circumvented by magnetically shielding the device, which is achieved by incorporating a soft magnetic material in the back cover of the cell phone.

SPINTEC is currently collaborating with IEEE Standard Association to establish a standard on magnetic field immunity of STT-MRAM, which will ease technical discussions between foundries providing the technology, chip manufacturers and end-users.

Team: MRAM

Collaboration:Everspin, Global Foundries, IMEC, Tohoku Univ., NUMEM, Univ.Austin Texas, HProbe, KAIST, Huawei, Netsol, Applied Materials, Univ.Arizona, IBM

Further reading: Impact of External Magnetic Fields on STT-MRAM, B. Dieny, S. Aggarwal, V.B. Naik, S. Couet, T. Coughlin, S. Fukami, K. Garello , J. Guedj, J.A.C. Incorvia, L. Lebrun, K-J. Lee, D. Leonelli, Y. Noh, S. Salimy, S. Soss, L. Thomas, W. Wang, and, D.l Worledge, IEEE Electrons devices Magazine (Sept 2024). Open access: hal- 04751421

Contact at Spintec: Bernard DIENY